If you’re a homeowner with a septic system or considering buying a property that uses one, understanding how does a septic tank work is essential for proper maintenance and avoiding costly repairs. This guide breaks down the septic system components and wastewater treatment process in simple terms.

We’ll walk you through the step-by-step journey your waste takes from toilet to drain field, explain how septic system bacteria naturally break down solids, and cover the essential septic tank maintenance tasks that keep everything running smoothly. You’ll also learn about septic tank design basics and why regular septic tank pumping and septic tank cleaning protect your investment for years to come.

Understanding Septic Tank Components and Design

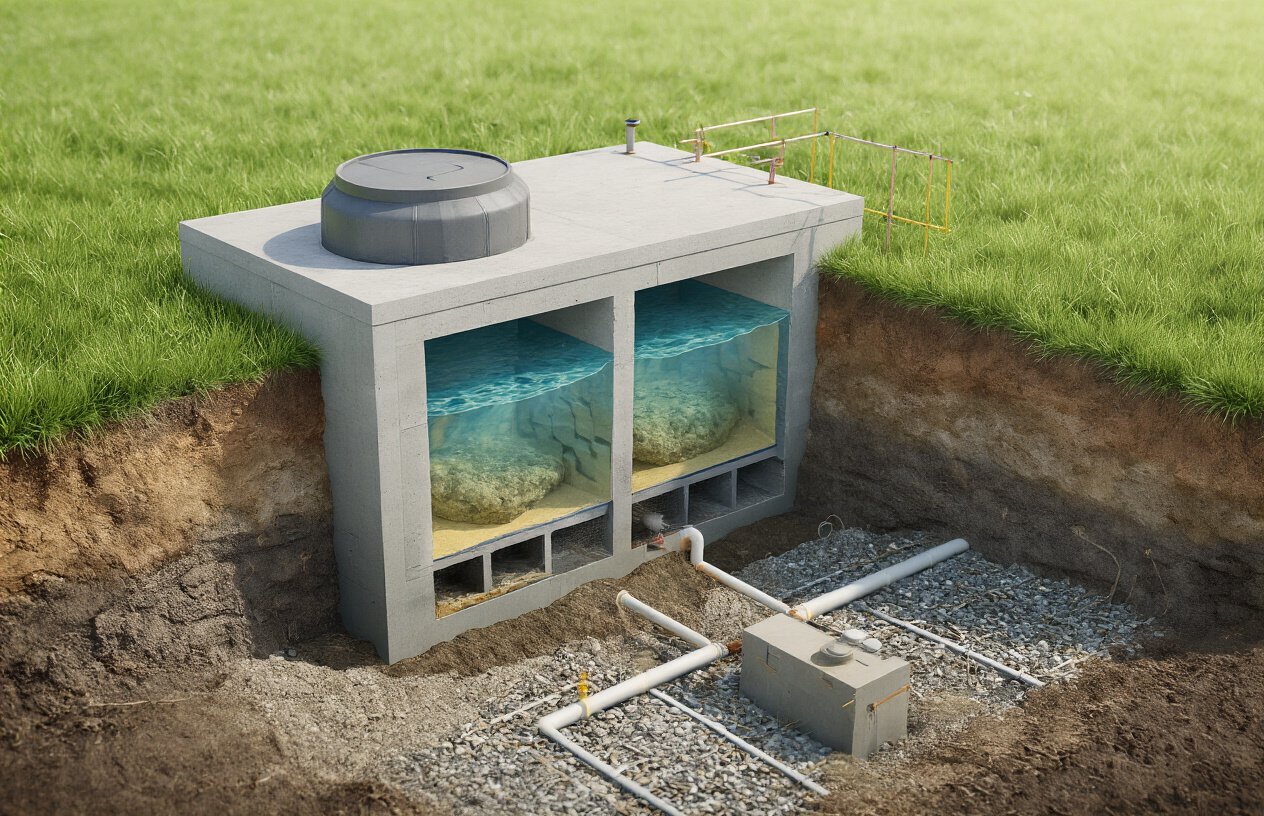

Three-Chamber Tank System Breakdown

Most modern septic tanks feature a three-chamber design that maximizes waste processing efficiency. The first chamber, also called the primary compartment, receives all incoming wastewater from your home. Here, the heaviest solids sink to the bottom forming sludge, while oils and grease float to the top creating a scum layer. The middle liquid layer contains partially clarified water.

The second chamber continues the settling process, allowing additional solids to separate from the liquid. This compartment acts as a buffer zone, giving bacteria more time to break down organic matter. The third chamber serves as the final polishing stage, where the cleanest effluent prepares for distribution to the drain field.

| Chamber | Primary Function | Key Process |

|---|---|---|

| Chamber 1 | Initial separation | Heavy settling, scum formation |

| Chamber 2 | Secondary treatment | Continued bacterial breakdown |

| Chamber 3 | Final clarification | Effluent polishing |

Inlet and Outlet Pipe Functions

The inlet pipe carries wastewater from your house directly into the septic tank’s first chamber. Positioned at a specific angle, this pipe creates proper flow dynamics that prevent turbulence from disturbing settled solids. The inlet typically sits 2-3 inches higher than the outlet pipe, creating a slight downward slope that encourages natural gravity flow.

The outlet pipe transfers partially treated effluent from the final chamber to your drain field. This pipe includes a filter or screen that prevents solids from escaping the tank. Proper outlet pipe positioning ensures only the clearest liquid layer exits the septic system, protecting your drain field from clogging.

Baffle System Importance

Baffles are vertical barriers inside your septic tank that direct wastewater flow and prevent surface scum from flowing into subsequent chambers. The inlet baffle forces incoming waste downward, preventing it from short-circuiting directly to the outlet. This downward flow pattern gives solids adequate time to settle properly.

Outlet baffles create a similar function in reverse, drawing effluent from the middle liquid zone while blocking floating scum and settled sludge. These components are critical for septic tank design effectiveness – without proper baffles, untreated waste could bypass the biological treatment process entirely.

Tank Size and Capacity Considerations

Septic tank capacity directly correlates with household size and daily water usage. A typical three-bedroom home requires a 1,000-gallon tank, while larger households need 1,250-1,500 gallon systems. The tank must provide enough retention time – usually 24-48 hours – for proper waste separation and bacterial breakdown.

Tank sizing also considers peak flow periods, like when multiple appliances run simultaneously. Undersized tanks can’t handle surge loads, causing solids to wash into the drain field. Oversized tanks may not maintain proper bacterial populations due to insufficient waste concentration for optimal microbial activity.

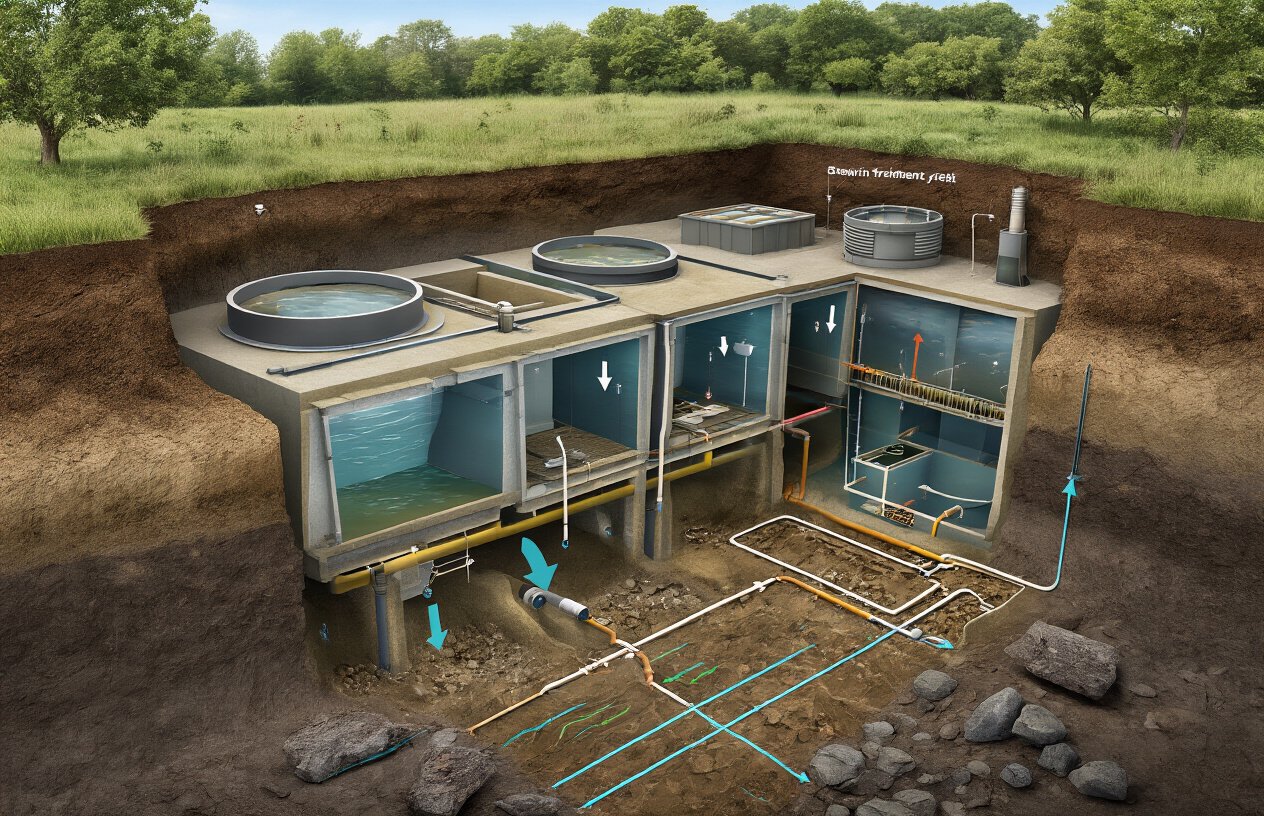

Step-by-Step Waste Processing Journey

Initial waste entry and separation process

When wastewater enters your septic tank from your home, the system immediately begins its first critical phase of treatment. All the water and waste from your toilets, sinks, showers, and washing machines flows through a single inlet pipe into the tank’s first chamber. This initial entry point creates turbulence that helps mix the incoming waste with the existing contents.

The moment wastewater enters the septic tank, gravity takes over and natural separation begins. Heavier solids like toilet paper, food particles, and human waste sink to the bottom of the tank, forming what’s called the sludge layer. Meanwhile, lighter materials such as oils, grease, soap scum, and other floating debris rise to the surface, creating the scum layer. Between these two distinct layers sits the middle zone – a relatively clear liquid called effluent that contains dissolved and suspended particles.

This three-layer system forms the foundation of how septic tanks work. The separation process happens continuously as new wastewater enters, but it takes time for materials to settle into their proper layers. The tank’s design includes baffles – concrete or plastic barriers – that help direct the flow of incoming waste and prevent the scum layer from flowing out with the treated water.

Primary treatment in the first chamber

The first chamber serves as the powerhouse of your septic system’s primary treatment process. Here, the separated waste undergoes its most intensive treatment phase through a combination of settling, decomposition, and bacterial action. This chamber typically holds about two-thirds of the tank’s total capacity, giving waste materials plenty of time to break down properly.

Anaerobic bacteria – microorganisms that thrive without oxygen – populate the sludge layer at the bottom of the first chamber. These beneficial bacteria work around the clock to decompose organic matter, breaking down complex waste materials into simpler compounds. The bacterial action produces gases like methane and hydrogen sulfide, which escape through your home’s plumbing vents.

During this primary treatment phase, the heaviest solids continue settling while the bacterial decomposition reduces the overall volume of waste. The process transforms solid organic matter into liquid and gas, significantly reducing the amount of material that needs further treatment. However, not everything breaks down completely – some inorganic materials and slower-decomposing solids accumulate over time, which is why regular septic tank pumping becomes necessary.

The retention time in the first chamber is crucial for effective treatment. Most septic tank designs ensure wastewater stays in this chamber for at least 24 hours, allowing sufficient time for settling and initial bacterial breakdown before moving to the next stage.

Secondary clarification and settling

The second chamber of your septic tank provides additional settling time and clarification for the partially treated wastewater. After flowing through a baffle or outlet from the first chamber, the effluent enters this secondary treatment zone where further separation and polishing occur. This chamber operates at a much calmer level than the turbulent first chamber, allowing even finer particles to settle out.

In the secondary chamber, any remaining suspended solids that escaped the first chamber’s treatment process get another chance to settle. The quieter environment helps capture particles that were too small or light to settle during the initial treatment phase. Additional bacterial action continues here, though at a reduced level compared to the heavily loaded first chamber.

The design of most septic tanks includes an outlet baffle that prevents scum and floating debris from leaving the tank with the treated effluent. This baffle system ensures only the clearest liquid from the middle layer exits the tank and flows toward the drain field. The effluent leaving the secondary chamber still contains dissolved nutrients and some bacteria, but it’s significantly cleaner than the raw wastewater that originally entered the system.

This secondary clarification process is essential for protecting your drain field from clogging. Without proper settling in both chambers, suspended solids would flow into the soil absorption system, potentially blocking the tiny pore spaces that allow wastewater treatment to continue in the soil.

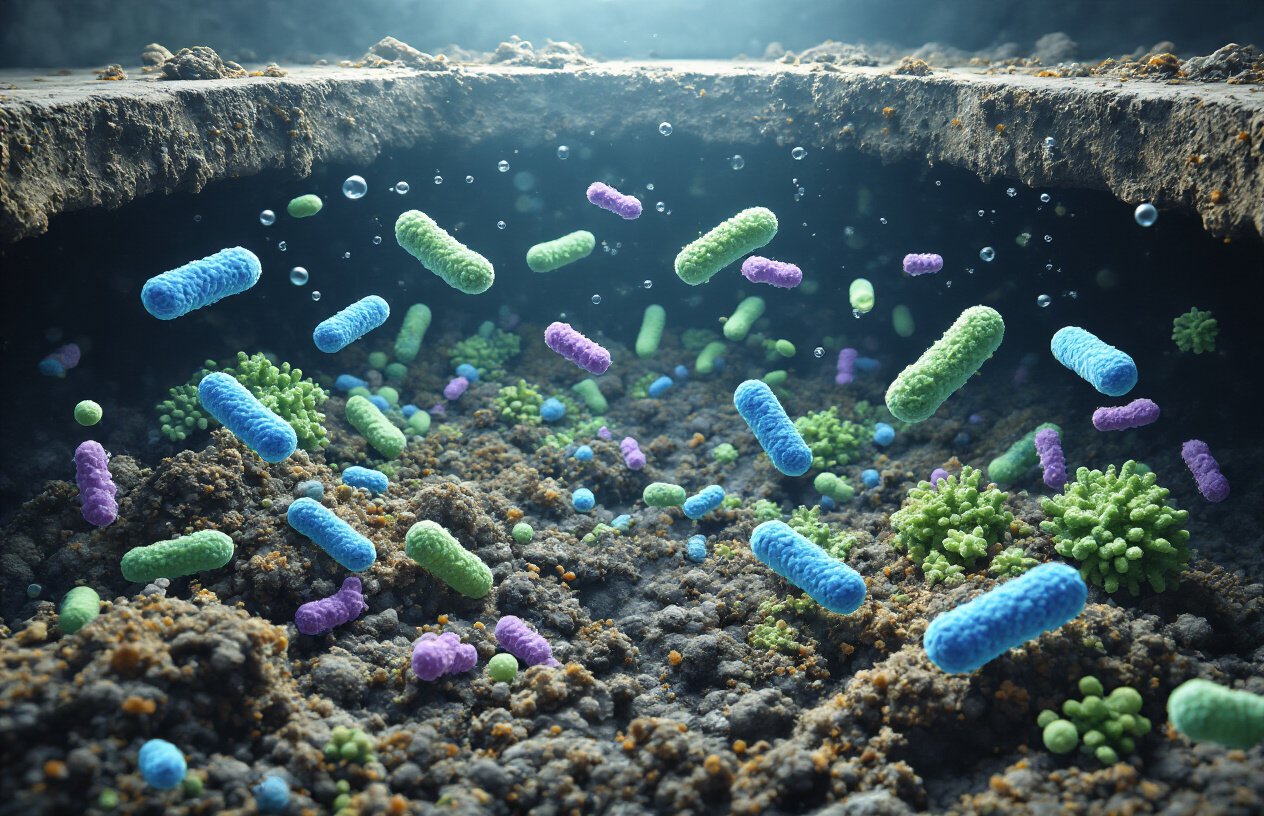

Natural Bacterial Action That Powers Your System

Anaerobic Bacteria Breakdown Process

Your septic tank operates like a massive biological factory powered by millions of hardworking anaerobic bacteria. These microscopic organisms thrive in oxygen-free environments, making them perfect for the sealed conditions inside your septic tank. Unlike their aerobic cousins that need air to survive, these bacteria break down organic matter without requiring any oxygen.

The anaerobic breakdown process happens slowly but efficiently. These bacteria consume organic waste materials, converting complex compounds into simpler substances like methane, carbon dioxide, and hydrogen sulfide. This process typically takes 24-48 hours for initial breakdown, though complete decomposition can take weeks or months depending on the waste type.

Temperature plays a crucial role in bacterial activity. Cold weather slows down the septic system bacteria, while warmer conditions accelerate the process. That’s why septic tanks in colder climates may need more frequent attention during winter months.

Sludge Layer Formation and Decomposition

The bottom layer of your septic tank contains sludge – a thick mixture of partially decomposed solids and bacterial waste. This layer forms naturally as heavier particles settle to the tank floor during the wastewater treatment process.

Anaerobic bacteria continuously work on this sludge layer, breaking down organic materials into smaller particles. However, they can’t eliminate everything. Inorganic materials like sand, grit, and non-biodegradable items accumulate over time, which is why regular septic tank pumping becomes necessary.

The sludge layer should occupy no more than one-third of your tank’s total volume. When it exceeds this level, the system’s efficiency drops significantly, and solid waste may flow into the drain field, causing expensive damage.

Scum Layer Management

At the top of your septic tank floats the scum layer, consisting of oils, grease, soap residue, and other lightweight materials. This layer forms a protective barrier that helps maintain the anaerobic environment below.

Bacterial action slowly breaks down components of the scum layer, but oils and grease prove particularly stubborn. Excessive grease from cooking or harsh chemicals can disrupt the natural bacterial balance, reducing the effectiveness of your septic system.

Proper scum layer management involves limiting what goes down your drains. Avoid pouring cooking oils, excessive soap, or chemical cleaners into your system, as these can overwhelm the bacteria’s ability to process waste effectively.

Effluent Quality Improvement

The bacterial breakdown process significantly improves effluent quality before it reaches your drain field. Raw wastewater entering the tank contains high levels of organic matter, harmful bacteria, and suspended solids that would contaminate soil and groundwater.

Through bacterial action, organic pollutants decrease by 40-60%, and harmful pathogens reduce substantially. The clarified liquid that flows to the drain field contains much lower concentrations of nitrogen, phosphorus, and organic compounds.

This natural biological treatment makes your septic tank an effective first-stage wastewater treatment system. The bacteria essentially pre-treat the water, making the final soil filtration process more manageable and environmentally safe.

Regular septic tank maintenance ensures these beneficial bacteria remain healthy and active, maintaining optimal effluent quality and protecting your property’s groundwater from contamination.

Drain Field Distribution and Soil Filtration

Effluent Discharge Into Distribution Box

After the septic tank completes its initial treatment process, the partially clarified wastewater (called effluent) flows into a distribution box. This concrete or plastic chamber serves as the traffic director for your septic system, evenly distributing the treated wastewater across multiple pipes that lead to the drain field.

The distribution box typically sits at a lower elevation than the septic tank, allowing gravity to move the effluent naturally. Inside this box, you’ll find multiple outlet pipes positioned at exactly the same height – this precise leveling ensures equal flow distribution. When effluent enters the box, it splits evenly among these outlets, preventing any single area of the drain field from becoming overloaded.

Most distribution boxes include inspection ports that allow technicians to check flow patterns and identify potential blockages. The box also contains baffles or flow control devices that help maintain steady distribution rates, even when water usage varies throughout the day.

Perforated Pipe Network Layout

The drain field consists of a carefully engineered network of perforated pipes, also called distribution lines or lateral lines. These pipes are typically 4 inches in diameter and made from PVC or corrugated plastic, with holes or slots spaced every few inches along their length.

The pipe layout follows specific design requirements based on soil conditions, household size, and local regulations. Most systems use a parallel distribution pattern, where pipes run side by side across the drain field area. Each pipe is typically 50 to 100 feet long and spaced 6 to 10 feet apart.

The pipes are buried in trenches filled with gravel or crushed stone aggregate. This gravel bed serves multiple purposes:

- Structural support: Protects pipes from soil pressure and damage

- Water storage: Temporarily holds effluent during peak discharge periods

- Pre-filtration: Removes larger particles before soil contact

- Air circulation: Maintains oxygen levels needed for bacterial activity

The entire network is covered with a permeable fabric or barrier to prevent soil from clogging the gravel bed while still allowing water infiltration.

Soil Absorption and Final Filtration

The soil beneath your drain field acts as the final treatment stage in your septic system. As effluent percolates down through different soil layers, physical, chemical, and biological processes remove remaining contaminants and pathogens.

Different soil types provide varying levels of filtration effectiveness:

| Soil Type | Percolation Rate | Filtration Quality | Considerations |

|---|---|---|---|

| Sandy soil | Fast (1-5 min/inch) | Good physical filtering | May need larger drain field |

| Loamy soil | Moderate (5-30 min/inch) | Excellent overall treatment | Ideal for septic systems |

| Clay soil | Slow (30+ min/inch) | Superior pathogen removal | Risk of system backup |

The top layer of soil contains the highest concentration of beneficial bacteria that break down organic matter and neutralize harmful microorganisms. As wastewater moves deeper, different soil layers continue the purification process through adsorption, where soil particles bind to contaminants, and ion exchange, where harmful substances are replaced with harmless minerals.

Proper soil absorption requires adequate oxygen levels, which is why drain field design includes specific depth requirements and spacing between pipes. The soil must remain unsaturated to maintain air pockets that support aerobic bacteria responsible for the final wastewater treatment stages.

Essential Maintenance Requirements for Optimal Performance

Regular Pumping Schedule Guidelines

Your septic tank needs regular pumping to remove accumulated solids that can’t break down naturally. Most residential systems require pumping every 3-5 years, though this varies based on household size, water usage, and tank capacity. A family of four with a 1,000-gallon tank typically needs septic tank pumping every 3-4 years.

Heavy water usage accelerates the need for pumping. Installing water-efficient fixtures and spreading out laundry loads helps extend the time between pump-outs. Keep detailed records of when your septic tank was last pumped – this information proves valuable for scheduling and helps technicians understand your system’s patterns.

Tank size directly impacts pumping frequency:

| Tank Size | Household Size | Pumping Frequency |

|---|---|---|

| 750 gallons | 1-2 people | 4-5 years |

| 1,000 gallons | 3-4 people | 3-4 years |

| 1,250 gallons | 5-6 people | 2-3 years |

Bacterial Balance Monitoring

Septic system bacteria perform the critical work of breaking down waste. These beneficial microorganisms need the right environment to thrive – proper pH levels, adequate moisture, and the right mix of nutrients. Avoid flushing antibacterial soaps, bleach, or chemical drain cleaners that kill these essential bacteria.

Signs of bacterial imbalance include slow drains, bad odors, and standing water in your drain field. Adding bacterial supplements can help restore balance, especially after antibiotic use or chemical exposure. However, a well-maintained system typically maintains healthy bacterial populations naturally.

Warning Signs of System Failure

Watch for these red flags that indicate your septic system needs immediate attention:

- Sewage backups in drains or toilets

- Foul odors around the septic tank or drain field

- Standing water or wet spots over the drain field

- Bright green grass growing unusually fast over the system

- Gurgling sounds from drains or toilets

- Slow drainage throughout the house

Don’t ignore these warning signs. Early intervention prevents costly repairs and protects your property value. Contact a septic professional immediately if you notice multiple symptoms.

Professional Inspection Recommendations

Schedule professional septic tank maintenance inspections every 1-3 years, even when your system seems to work perfectly. Licensed technicians check sludge levels, inspect baffles and pipes, and assess the overall system health. They can spot problems before they become expensive emergencies.

During inspections, professionals measure scum and sludge layers, check for leaks, and examine the drain field condition. They’ll also verify that all components function properly and recommend any needed repairs. Annual inspections cost significantly less than system replacement or environmental cleanup.

Conclusion

Your septic system works like a well-orchestrated underground team, with each component playing its part to safely process your household waste. From the main tank where solids settle and bacteria do their magic, to the drain field where soil acts as nature’s final filter, every step depends on biological processes that have been perfecting themselves for millions of years. The beauty of this system lies in its simplicity – when bacteria break down waste and soil filters the remaining water, you get an effective treatment process that happens right on your property.

Regular maintenance is what keeps this underground ecosystem thriving. Simple actions like pumping every few years and being mindful of what goes down your drains can save you thousands in repairs and keep your system running smoothly for decades. Take care of your septic system, and it’ll take care of you – it’s really that straightforward.